In the realm of plumbing, the choice of materials and fittings can significantly impact the efficiency and longevity of water supply systems. Among the various options available, the combination of PPR (Polypropylene Random Copolymer) female socket couplings with brass pipe fittings stands out for its durability and versatility. This article explores the features, benefits, and applications of PPR fittings, especially the female socket coupling, and how brass fittings enhance their performance in cold and hot water feeding systems.

1. Understanding PPR Fittings

1.1. What Are PPR Fittings?

PPR fittings are essential components in plumbing systems, made from polypropylene, a type of plastic known for its strength and resistance to various chemicals. These fittings are designed to connect pipes in a secure manner, ensuring a leak-free and efficient flow of water. PPR fittings are lightweight, easy to install, and resistant to corrosion, making them an ideal choice for modern plumbing applications.

1.2. Types of PPR Fittings

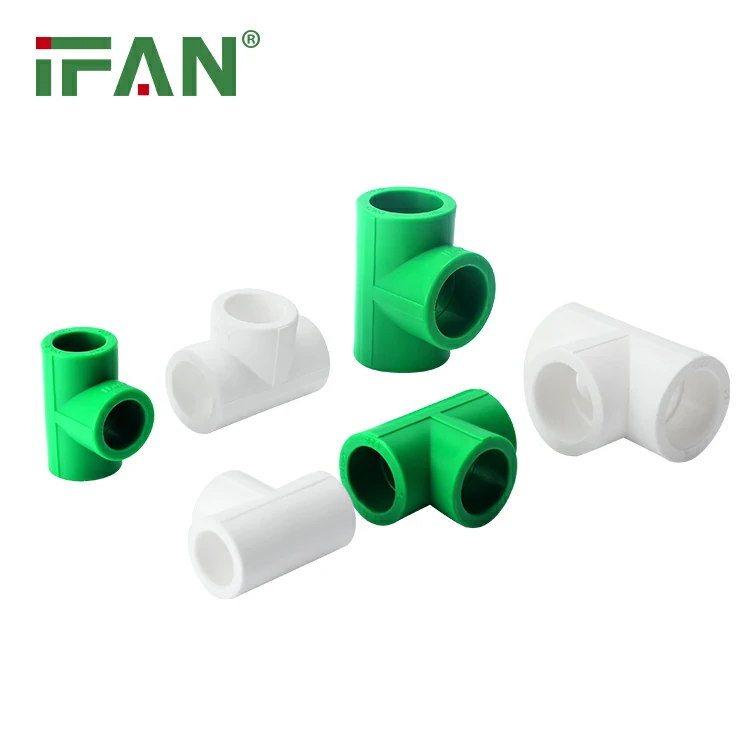

PPR fittings come in various shapes and sizes to accommodate different plumbing needs. Some common types include:

- Elbows: Used to change the direction of the piping system.

- Tees: Allow for branching off into different directions.

- Couplings: Connect two sections of pipe together.

Among these, the female socket coupling is particularly important for joining pipes and providing a secure connection.

2. The Female Socket Coupling

2.1. Features of PPR Female Socket Couplings

PPR female socket couplings are designed to fit over the ends of pipes, creating a tight seal. Key features include:

- Ease of Installation: These couplings can be easily welded or joined to PPR pipes using heat fusion methods.

- Durability: PPR fittings are resistant to high pressure and temperature, making them suitable for both cold and hot water applications.

- Chemical Resistance: They can withstand exposure to various chemicals, ensuring longevity in diverse environments.

2.2. Applications of PPR Female Socket Couplings

PPR female socket couplings are widely used in various applications, including:

- Residential Plumbing: Ideal for connecting pipes in homes, ensuring a reliable water supply.

- Commercial Buildings: Used in office buildings and institutions for efficient water distribution.

- Industrial Applications: Suitable for transporting chemicals and other fluids in industrial settings.

3. The Role of Brass Pipe Fittings

3.1. What Are Brass Pipe Fittings?

Brass pipe fittings are made from an alloy of copper and zinc, known for their strength and resistance to corrosion. They are commonly used in plumbing systems to connect pipes and control the flow of water. Brass fittings are particularly valued for their durability and ability to withstand high pressure and temperature variations.

3.2. Benefits of Using Brass Fittings with PPR

Combining PPR female socket couplings with brass fittings offers several advantages:

- Enhanced Durability: Brass fittings provide a robust connection that can withstand high pressure and temperature, ensuring the integrity of the plumbing system.

- Corrosion Resistance: The natural resistance of brass to corrosion extends the lifespan of the plumbing system, particularly in environments where water quality may be a concern.

- Versatility: Brass fittings can be used with various pipe materials, including PPR, allowing for flexible plumbing designs.

4. Installation Process for PPR Female Socket Coupling with Brass Fittings

4.1. Preparation

Before installation, ensure that you have all necessary tools and materials, including:

- PPR pipes and female socket couplings

- Brass fittings

- Pipe cutter

- Heat fusion tool (for PPR)

- Wrench (for brass fittings)

4.2. Steps for Installation

- Cut the PPR Pipe: Use a pipe cutter to cut the PPR pipe to the desired length, ensuring a clean, straight edge.

- Prepare the Fittings: Clean the ends of the PPR pipe and the interior of the female socket coupling to remove any debris.

- Heat Fusion: Use a heat fusion tool to heat the ends of the PPR pipe and the female socket coupling until they reach the appropriate temperature. Quickly join them together, applying even pressure to create a secure bond.

- Attach Brass Fittings: Once the PPR coupling is securely attached, use a wrench to connect the brass fitting to the other end of the coupling, ensuring a tight seal.

- Testing: After installation, test the system for leaks by running water through the pipes.

5. Advantages of Using PPR Female Socket Couplings with Brass Fittings

5.1. Cost-Effectiveness

The combination of PPR fittings with brass fittings can lead to significant cost savings. PPR pipes are generally less