PPR pipes are a type of plastic pipe that are commonly used for plumbing systems in buildings. They are known for their durability, high temperature and pressure resistance, and long lifespan. Advancements in PPR pipe technology have made them an even better option for hot and cold water systems in recent years.

In this article, we will explore the advancements in PPR pipe technology for hot and cold water systems and discuss the benefits they provide.

What Is PPR Pipe Technology?

PPR stands for polypropylene random copolymer. It is a type of plastic that is widely used for pipes, fittings, and valves in plumbing systems. PPR pipes are made from a combination of propylene and ethylene that have been polymerized together. This gives them a unique combination of properties, such as high temperature and pressure resistance, flexibility, and durability.

The Advancements In PPR Pipe Technology

Over the years, advancements have been made in the technology used to manufacture PPR pipes. Here are some of the most notable advancements:

Improved manufacturing processes: Manufacturers have developed new methods for producing PPR pipes that improve their quality, consistency, and durability. For example, some manufacturers use advanced injection molding technology to produce pipes that have a smoother interior surface and fewer defects.

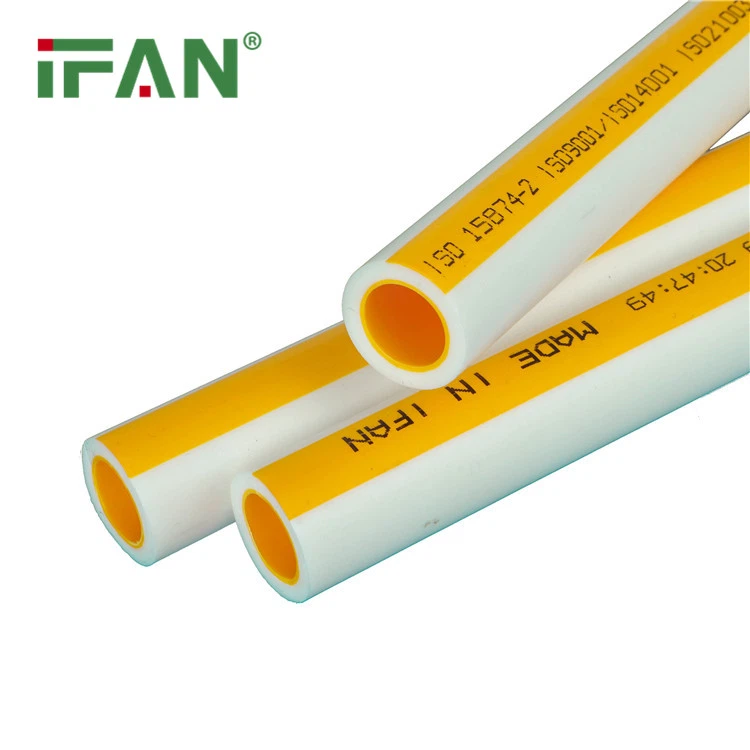

New materials: PPR pipes are now being made with advanced materials that provide even greater strength, resistance to UV radiation, and thermal conductivity. Some of these materials include glass fiber reinforced polypropylene, which provides excellent mechanical strength and dimensional stability, and aluminum-plastic composite PPR pipes, which have excellent heat transfer properties.

Enhanced fittings: Fittings are an important component of any plumbing system, and advancements have been made in PPR pipe fittings as well. Some manufacturers have developed fittings that are easier to install, require fewer tools, and provide better connections.

Benefits Of Using Advanced PPR Pipe Technology

The advancements in PPR pipe technology have several benefits for hot and cold water systems:

Improved durability: PPR pipes made with advanced technology are more durable and have a longer lifespan than older types of pipes. They are resistant to cracking, warping, and leaking, and can withstand high temperatures and pressures.

Greater flexibility: PPR pipes made with new materials are more flexible than older types of pipes, which makes them easier to install in tight spaces and around corners.

Better thermal conductivity: Some PPR pipes made with advanced materials have better thermal conductivity, which means they can transfer heat more efficiently. This makes them an excellent choice for hot water systems, as they can help to reduce energy costs.

Higher resistance to UV radiation: PPR pipes made with advanced materials are highly resistant to UV radiation, which means they can be used in outdoor plumbing systems without the risk of degradation.

Improved fittings: Advanced PPR pipe fittings are easier to install and provide better connections than older types of fittings. This can reduce installation time and minimize the risk of leaks.

Conclusion

Advancements in PPR pipe technology have made them an even better choice for hot and cold water systems. The improved manufacturing processes, new materials, and enhanced fittings have made PPR pipes more durable, flexible, and thermally efficient. Using advanced PPR pipe technology can help to reduce energy costs, minimize the risk of leaks, and provide long-lasting plumbing systems.