PPR pipe, or PolyPropylene Random Copolymer Pipe, has emerged as a cutting-edge choice for modern plumbing systems, offering unparalleled performance and longevity. As the industry continues to evolve, PPR pipe stands out as a future-proof solution that meets the demands of today’s sophisticated fluid transfer needs.

Innovative Material Composition

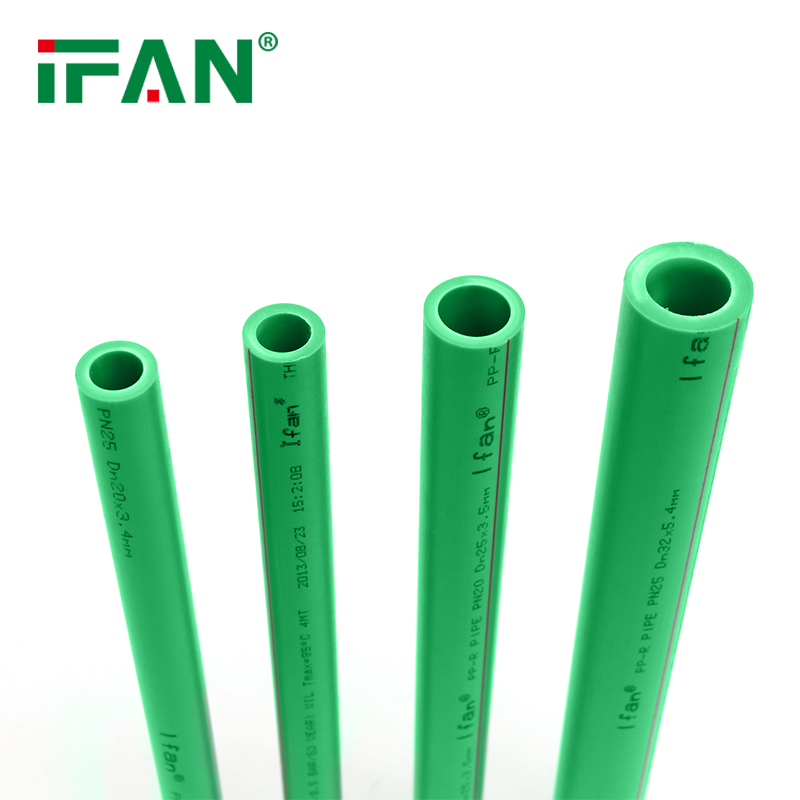

PPR pipe is made from PolyPropylene Random Copolymer, a high-performance plastic that combines exceptional strength with flexibility. This material is engineered to resist corrosion, chemical attack, and mechanical stress, ensuring reliable performance over extended periods of time. Its unique composition also allows for better thermal expansion and contraction, minimizing the risk of leaks and damage.

Durability and Longevity

PPR pipe is renowned for its durability and longevity, thanks to its robust material properties. It is able to withstand high pressures and temperatures without compromising performance or structural integrity. This makes it a suitable choice for a wide range of applications, including hot and cold water supply, heating systems, and industrial fluid transfer.

Ease of Installation and Maintenance

PPR pipe offers significant advantages in terms of installation and maintenance. Its lightweight design and flexible nature allow for easy handling and installation in tight spaces. Moreover, PPR pipe can be joined using fusion welding techniques, creating strong and leak-free connections. This eliminates the need for threading, soldering, or other traditional joining methods, significantly reducing installation time and costs. Once installed, PPR pipe requires minimal maintenance, ensuring smooth and efficient operation for years to come.

Environmental Sustainability

In today’s environmentally conscious world, PPR pipe offers an eco-friendly solution for plumbing systems. It is made from recyclable materials and can be easily recycled at the end of its service life. Additionally, PPR pipe does not contain any toxic or hazardous substances, ensuring safe use in potable water systems.

Conclusion

PPR pipe represents a cutting-edge choice for modern plumbing systems. Its innovative material composition, durability, ease of installation and maintenance, and environmental sustainability make it a future-proof solution that meets the demands of today’s sophisticated fluid transfer needs. As the industry continues to evolve, PPR pipe will undoubtedly play a crucial role in shaping the future of plumbing systems.

Free Sample(Click Here to Get Free Sample)