Introduction to HDPE Pipes and Fittings

HDPE (High-Density Polyethylene) pipes and fittings have become the go-to choice for numerous applications across various industries. Their unique properties and benefits have made them a preferred material for plumbing, water distribution, gas transmission, and many more. This article delves into the intricacies of HDPE pipes and fittings, providing a comprehensive industry overview.

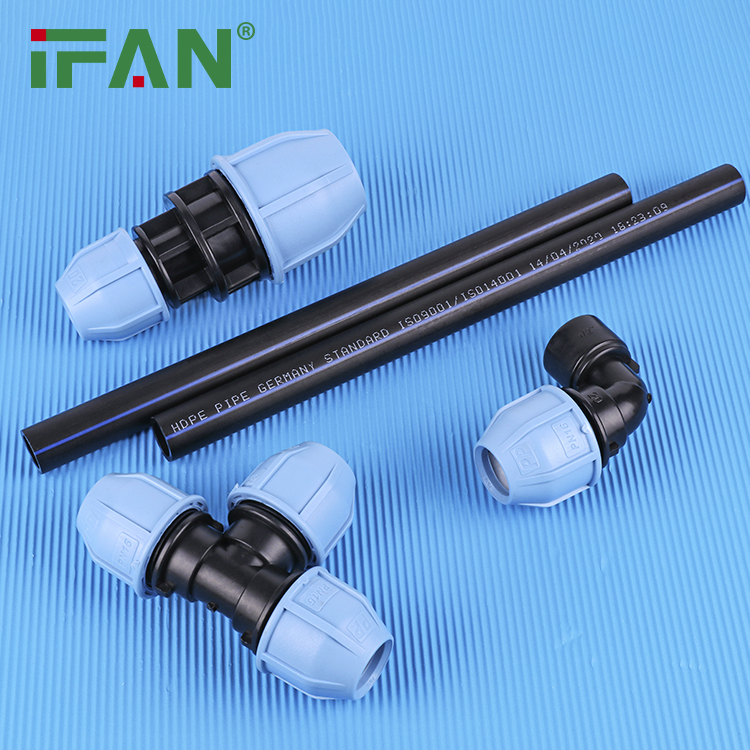

What Are HDPE Pipes and Fittings?

HDPE pipes are constructed from high-density polyethylene, a thermoplastic polymer renowned for its durability and flexibility. HDPE fittings, on the other hand, are the connectors that join these pipes, creating a secure and leak-proof system.

Unique Properties of HDPE

- Durability: HDPE is highly resistant to corrosion, abrasion, and chemicals, ensuring long-lasting performance.

- Flexibility: The material’s thermoplastic nature allows for easy installation in tight spaces and around curves.

- Lightweight: Compared to traditional materials like steel, HDPE is significantly lighter, making it easier to handle and transport.

Applications of HDPE Pipes and Fittings

- Water and Wastewater Systems: HDPE pipes are extensively used in potable water distribution, irrigation, and drainage systems due to their resistance to corrosion and long-term durability.

- Gas Transmission: HDPE pipes are also suitable for gas transmission, as they can withstand high pressures and are resistant to chemical attack.

- Industrial Applications: In industries like mining, chemical processing, and oil & gas, HDPE pipes and fittings provide a reliable and cost-effective solution for fluid handling.

Advancements in HDPE Technology

- Enhanced Material Properties: Researchers are constantly working to improve the performance of HDPE by developing new formulations and additives.

- Innovative Fitting Designs: Manufacturers are introducing new fitting designs that are easier to install and provide better sealing performance.

- Environmental Considerations: With increasing emphasis on sustainability, HDPE pipes and fittings are being designed to be more recyclable and environmentally friendly.

Future Prospects of HDPE Pipes and Fittings

The global demand for HDPE pipes and fittings is expected to grow significantly in the coming years. With their superior properties and numerous applications, HDPE is poised to become an even more important material in the piping industry.

In conclusion, HDPE pipes and fittings offer a reliable, cost-effective, and environmentally friendly solution for various piping applications. With continuous advancements in technology and material science, HDPE’s potential in the industry is bound to increase further.