PPR Fiberglass Pipes vs. Traditional Pipes: A Comparative Analysis

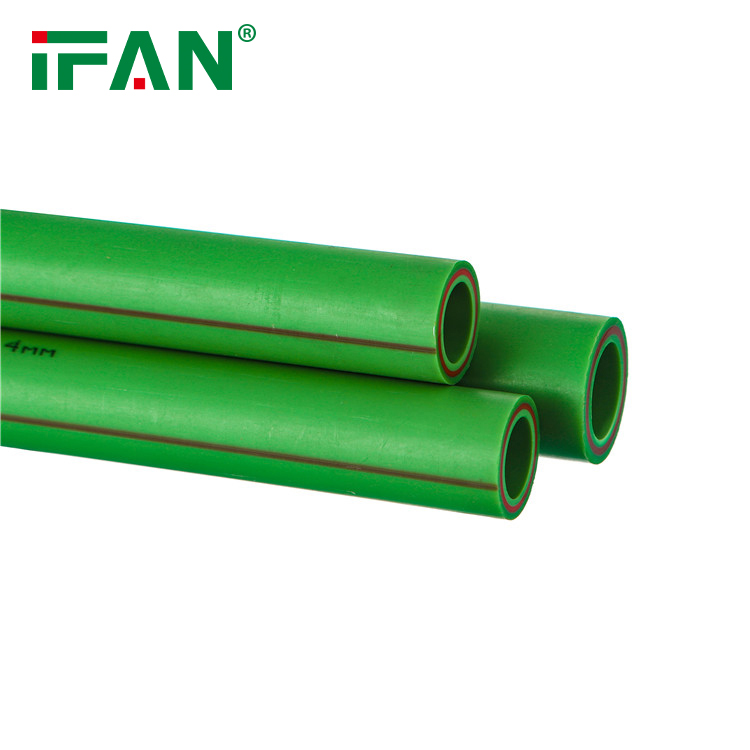

PPR (Polypropylene Random Copolymer) fiberglass pipes have emerged as a modern alternative to traditional pipes in various industries. These innovative pipes offer unique advantages over traditional options, such as metal or PVC pipes. In this comparative analysis, we will explore the key differences and benefits of PPR fiberglass pipes in comparison to traditional pipes. Let’s break down each section into separate headings.

1. Material Composition

Traditional pipes are commonly made from materials such as metal or PVC, which have their limitations. PPR fiberglass pipes, on the other hand, combine the strength and durability of fiberglass reinforcement with the excellent chemical resistance and thermal stability of PPR material. This combination creates a pipe that is highly resistant to corrosion, heat, and chemical degradation, making it suitable for a wide range of applications.

2. Flexibility and Ease of Installation

One notable advantage of PPR fiberglass pipes is their flexibility. They have a higher degree of flexibility compared to traditional pipes, making them easier to install, especially in complex and curved piping systems. The flexibility of PPR fiberglass pipes allows for easier maneuverability, reducing the need for additional fittings and connectors during installation.

3. Lightweight and Cost Efficiency

PPR fiberglass pipes are significantly lighter than traditional materials like metal. This lightweight nature makes handling and transportation of these pipes more convenient and cost-effective. It also simplifies the installation process, reducing the labor and equipment required. The reduced weight of PPR fiberglass pipes also contributes to lower shipping costs.

4. Excellent Insulation Properties

PPR fiberglass pipes exhibit excellent insulation properties, both thermally and acoustically. The fiberglass reinforcement acts as a thermal barrier, reducing heat transfer and minimizing energy loss. Additionally, the combination of PPR material and fiberglass reinforcement helps to dampen noise transmission, making PPR fiberglass pipes a suitable choice for plumbing systems in residential and commercial buildings.

5. Longevity and Durability

Traditional pipes may degrade over time due to corrosion, chemical exposure, or external factors. PPR fiberglass pipes, on the other hand, have exceptional longevity and durability. The PPR material is highly resistant to chemical degradation, ensuring the pipes’ performance and longevity in harsh environments. The fiberglass reinforcement provides added strength, enabling the pipes to withstand high pressures and impacts without deformation or leakage.

6. Low Maintenance and Reduced Downtime

PPR fiberglass pipes require minimal maintenance compared to traditional pipes. They do not corrode, rust, or scale, eliminating the need for regular inspections and repairs. Additionally, the smooth inner surface of PPR fiberglass pipes prevents the accumulation of deposits and reduces the risk of clogging, ensuring a continuous and efficient flow of fluids. The reduced maintenance requirements translate to reduced downtime and increased productivity for industries.

7. Environmental Considerations

In terms of environmental impact, PPR fiberglass pipes offer several advantages. The production of PPR material involves fewer harmful emissions compared to traditional pipe materials. Moreover, PPR fiberglass pipes are recyclable, reducing waste and promoting sustainability. Their long lifespan also reduces the need for frequent replacements, further minimizing their environmental footprint.

Conclusion

In conclusion, PPR fiberglass pipes provide superior performance and numerous benefits compared to traditional pipes. Their unique material composition, flexibility, lightweight nature, excellent insulation properties, longevity, low maintenance requirements, and positive environmental impact make them a reliable and sustainable choice for various applications. By opting for PPR fiberglass pipes, industries can enjoy improved efficiency, reduced costs, and increased durability in their piping systems