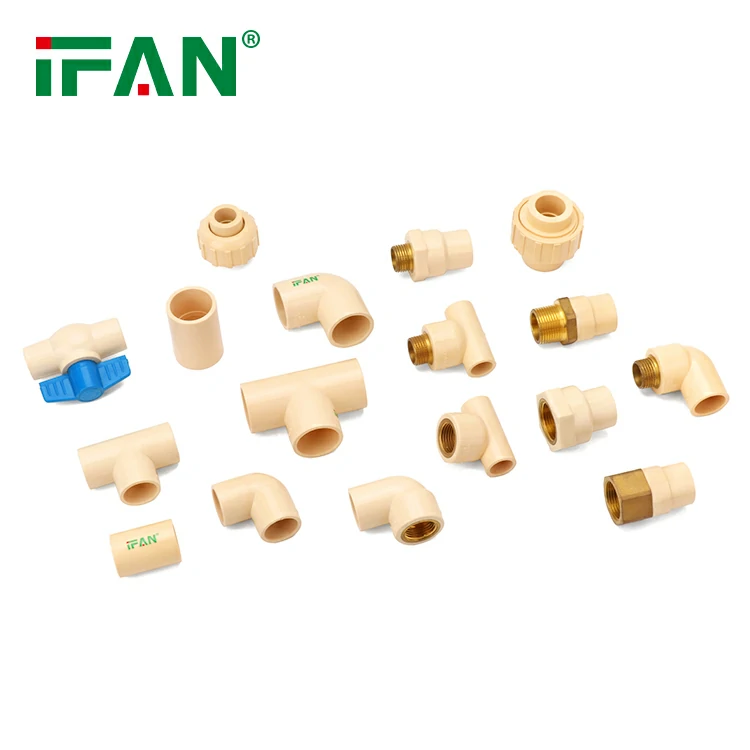

Description

IFAN factory 30+ years manufacture experience support color /size customization support free sample.Welcome to consult for catalog and free samples.This is our Facebook Website:www.facebook.com,Click to watch IFAN’s product video.Compared with Tomex products, our IFAN products from quality to price are your best choice, welcome to buy!

CPVC (Chlorinated Polyvinyl Chloride) fittings have become a cornerstone of modern plumbing systems, particularly in applications requiring high-temperature resistance. But what makes CPVC fittings so effective in handling heat? This article delves into the science behind CPVC fittings, explaining their unique properties and comparing them to alternatives like PPR fittings.

Understanding CPVC: A Material Built for Heat

CPVC is a thermoplastic material derived from PVC (Polyvinyl Chloride) through a chlorination process. This process introduces chlorine atoms into the polymer structure, enhancing its thermal and chemical properties. The result is a material that can withstand temperatures up to 200°F (93°C) or higher, making it ideal for hot water systems and industrial applications.

The Science of High-Temperature Resistance

1. Molecular Structure

The chlorination process alters the molecular structure of PVC, increasing its chlorine content from 56% to around **63-69%**. This change strengthens the material’s bond stability, allowing it to resist degradation at higher temperatures.

2. Glass Transition Temperature (Tg)

CPVC has a higher glass transition temperature (Tg) compared to standard PVC and **PPR fittings**. The Tg is the point at which a material transitions from a rigid state to a more flexible one. For CPVC, this temperature is approximately **110°C (230°F)**, significantly higher than PPR’s Tg of around 60°C (140°F).

3. Thermal Conductivity

CPVC has low thermal conductivity, meaning it does not easily transfer heat. This property helps maintain the temperature of the fluid inside the pipes while protecting the external environment from heat exposure.

4. Chemical Stability

The chlorination process also enhances CPVC’s chemical stability, making it resistant to acids, bases, and other corrosive substances. This stability contributes to its ability to perform reliably in high-temperature environments.

CPVC vs. PPR Fittings: A Temperature Comparison

While PPR fittings (Polypropylene Random Copolymer) are known for their flexibility and ease of installation, they fall short in high-temperature applications:

– Temperature Tolerance: PPR fittings typically have a maximum operating temperature of **70°C (158°F)**, significantly lower than CPVC’s 93°C (200°F).

– Thermal Expansion: PPR fittings expand more under heat, which can lead to system instability over time. CPVC, on the other hand, has lower thermal expansion, ensuring a more stable and durable system.

– Longevity in Hot Water Systems: CPVC’s superior heat resistance makes it a better choice for hot water plumbing, as it maintains its structural integrity over time.

Applications of CPVC Fittings in High-Temperature Environments

CPVC fittings are widely used in applications where temperature resistance is critical:

– Residential Hot Water Systems: CPVC is the material of choice for delivering hot water to homes due to its durability and safety.

– Industrial Processes: In industries such as chemical processing and manufacturing, CPVC fittings handle high-temperature fluids with ease.

– Commercial Buildings: Large-scale plumbing systems in hotels, hospitals, and schools rely on CPVC for reliable hot water distribution.

Safety and Efficiency Benefits

1. Leak-Proof Performance

CPVC fittings are designed to create secure, leak-proof connections, even under high temperatures. This reduces the risk of water damage and ensures system efficiency.

2. Non-Toxic Material

CPVC is a safe, non-toxic material that does not leach harmful chemicals into the water supply, making it ideal for potable water systems.

3. Fire Resistance

CPVC’s inherent fire-resistant properties add an extra layer of safety, particularly in high-risk environments.

Conclusion

The science behind CPVC fittings reveals why they are exceptionally well-suited for high-temperature applications. Their unique molecular structure, high glass transition temperature, and chemical stability make them a superior choice over alternatives like PPR fittings. Whether for residential, commercial, or industrial use, CPVC fittings offer unmatched performance, safety, and durability in hot water systems and beyond.

FAQs

1. What is the maximum temperature CPVC fittings can withstand?

CPVC fittings can withstand temperatures up to 200°F (93°C), making them ideal for hot water systems.

2. How does CPVC compare to PPR fittings in high-temperature applications?

CPVC fittings have a higher temperature tolerance and lower thermal expansion compared to PPR fittings, making them more stable and durable in high-temperature environments.

3. Are CPVC fittings safe for drinking water?

Yes, CPVC fittings are made from non-toxic materials and are safe for use in potable water systems.

4. Why does CPVC have better heat resistance than standard PVC?

The chlorination process increases CPVC’s chlorine content, strengthening its molecular bonds and raising its glass transition temperature.

5. Can CPVC fittings be used in industrial applications?

Absolutely. CPVC’s chemical stability and high-temperature resistance make it suitable for industrial processes involving hot fluids and corrosive substances.

By understanding the science behind CPVC fittings, you can make informed decisions for your plumbing needs, ensuring a safe, efficient, and long-lasting system.

Related products

-

CPVC ASTM2846

Redefining Piping Excellence: CPVC Fitting Socket

-

CPVC ASTM2846

Cpvc heat resistant temperature