Description

IFAN factory 30+ years manufacture experience support color /size customization support free sample.Welcome to consult for catalog and free samples.This is our Facebook Website:www.facebook.com,Click to watch IFAN’s product video.Compared with Tomex products, our IFAN products from quality to price are your best choice, welcome to buy!

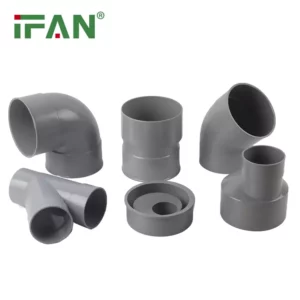

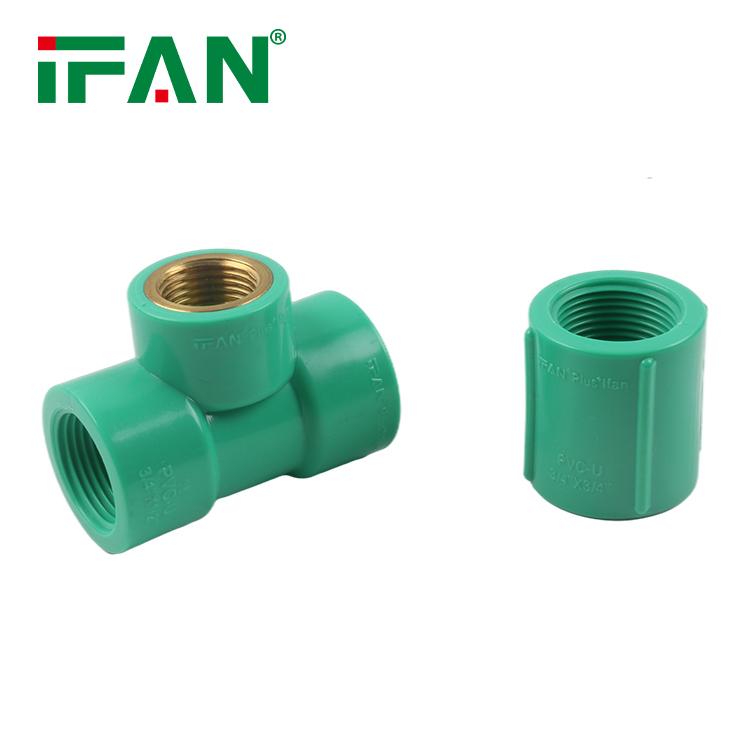

uPVC (unplasticized polyvinyl chloride) fittings are widely used in plumbing, drainage, and construction applications due to their durability, resistance to corrosion, and low maintenance needs. However, to ensure that these fittings perform effectively and safely, they must adhere to specific industry standards. This article explores the various standards governing uPVC fittings, their significance, and how they impact performance and safety.

1. Importance of Industry Standards

Industry standards for uPVC fittings are crucial as they establish minimum requirements for quality, safety, and performance. These standards are developed by various organizations, including international bodies like ISO (International Organization for Standardization) and regional standards such as ASTM (American Society for Testing and Materials) and EN (European Norms). Compliance with these standards ensures that products are reliable and safe for consumers, reducing the risk of failures and associated costs in both residential and commercial settings. Furthermore, adherence to these standards can enhance manufacturer credibility and facilitate market access.

2. Material Specifications

One of the primary aspects of uPVC fitting standards is the specification of materials used in their production. Standards dictate the chemical composition, physical properties, and performance metrics of uPVC. For example, the ISO 1452 standard outlines the requirements for pipes and fittings made from unplasticized polyvinyl chloride for use in water supply and drainage. These specifications ensure that the uPVC has adequate mechanical strength, impact resistance, and thermal stability, which are essential for maintaining integrity under various environmental conditions. Manufacturers must conduct rigorous testing to confirm that their products meet these material standards before they can be marketed.

3. Testing and Certification Procedures

To ensure compliance with established standards, uPVC fittings undergo a variety of testing procedures. These tests assess factors such as pressure resistance, temperature tolerance, and long-term durability. For instance, the ASTM D1784 standard provides rigorous testing protocols for plastic piping materials, including tests for tensile strength, impact resistance, and hydrostatic pressure. Once tested, products that meet the standards may receive certification from recognized bodies, which enhances consumer confidence. Regular audits and re-testing are also necessary to maintain certification, ensuring continuous compliance throughout the product’s lifecycle.

4. Installation and Performance Guidelines

Standards also encompass guidelines for the proper installation and usage of uPVC fittings. The correct installation practices are essential for preventing leaks, ensuring system efficiency, and prolonging the lifespan of the fittings. For example, standards like the AS/NZS 1260 provide detailed guidance on installing uPVC pipes and fittings in drainage systems, addressing issues such as jointing methods, bedding requirements, and alignment. Following these guidelines helps mitigate risks associated with improper installation, such as pipe failure or water contamination, thereby safeguarding public health and infrastructure.

5. Environmental Considerations

In recent years, there has been an increasing focus on sustainability and environmental impact in the manufacturing and use of uPVC fittings. Standards have evolved to include guidelines for the recyclability and environmental footprint of uPVC products. For instance, ISO 14001 outlines requirements for an effective environmental management system, encouraging manufacturers to minimize waste and energy consumption during production. Additionally, standards related to the life cycle assessment of materials help manufacturers and consumers understand the overall environmental impact of uPVC fittings from production to disposal. By adhering to these environmental standards, companies can contribute to sustainability efforts while potentially gaining a competitive advantage in the market.

Conclusion

Understanding the standards for uPVC fittings is essential for manufacturers, suppliers, and consumers alike. These standards ensure that products are safe, reliable, and effective for their intended applications. By adhering to material specifications, undergoing rigorous testing, following installation guidelines, and considering environmental impacts, stakeholders can ensure the quality and sustainability of uPVC fittings. As the demand for durable and efficient plumbing solutions continues to grow, adherence to these standards will play a pivotal role in the development and use of uPVC fittings in various applications.