ISO 15874 PPR vs PVC Pipes: A Comparative Study

Whatsapp Us

Share

Description

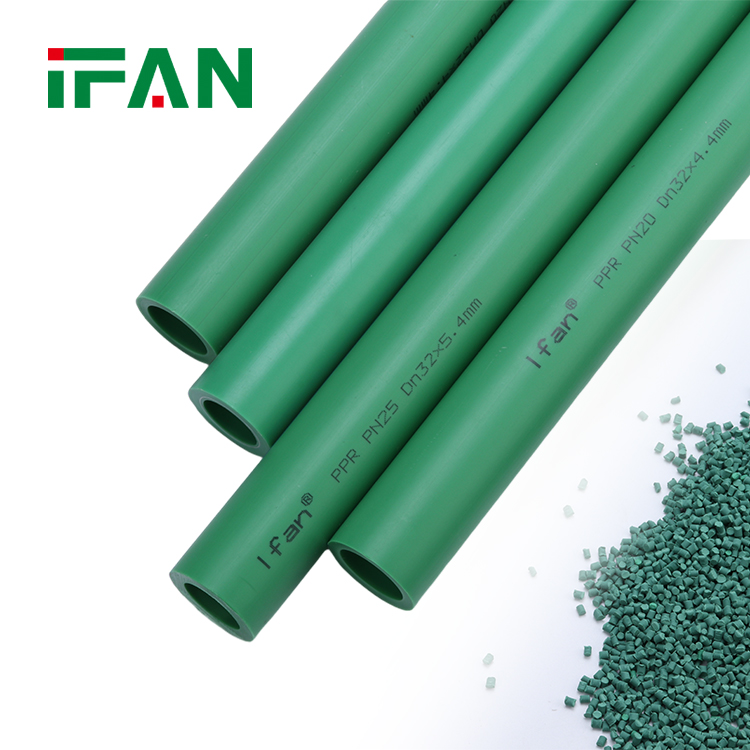

IFAN factory 30+ years manufacture experience support color /size customization support free sample.Welcome to consult for catalog and free samples.This is our Facebook Website:www.facebook.com,Click to watch IFAN’s product video.Compared with Tomex products, our IFAN products from quality to price are your best choice, welcome to buy!

When it comes to choosing the right piping material for plumbing or construction projects, PPR pipes (Polypropylene Random Copolymer) and PVC pipes (Polyvinyl Chloride) are two of the most popular options available in the market. Both materials offer a variety of benefits, but they also come with distinct features that can make one more suitable than the other for specific applications. In this article, we will conduct a comparative study of PPR vs PVC pipes, highlighting their strengths, weaknesses, and ideal use cases.

What are PPR Pipes?

PPR pipes are made from polypropylene random copolymer, a thermoplastic material that is highly durable, resistant to chemical corrosion, and capable of withstanding high temperatures. PPR pipes are commonly used in plumbing, heating systems, and potable water supply systems. Their resistance to pressure and temperature fluctuations makes them a popular choice for both residential and industrial applications.

Advantages of PPR Pipes

1. Durability: PPR pipes are highly resistant to corrosion, scaling, and damage from various chemicals. They are long-lasting, with a lifespan that can reach up to 50 years.

2. Temperature Resistance: PPR pipes can handle hot water applications, making them ideal for heating systems, as they can withstand temperatures up to 95°C (203°F) without deforming.

3. Environmentally Friendly: Made from recyclable materials, PPR pipes are considered an eco-friendly option compared to other plastics.

4. Leak-Free Connections: The fusion welding method used to connect PPR pipes ensures strong, leak-free joints, which results in a more secure and durable plumbing system.

What are PVC Pipes?

PVC pipes are made from polyvinyl chloride, a widely used plastic material known for its lightweight, cost-effective, and durable properties. They are commonly used in sewer systems, drainage, irrigation, and cold water distribution. **PVC pipes** are also available in a variety of grades, such as Schedule 40 and Schedule 80, to accommodate different pressure and load-bearing requirements.

Advantages of PVC Pipes

1. Cost-Effective: PVC pipes are more affordable than PPR pipes, making them a go-to option for projects with budget constraints.

2.Corrosion Resistance: PVC pipes are resistant to rust and corrosion, which makes them suitable for water and sewage applications.

3. Lightweight: Due to their low weight, PVC pipes are easier to transport and handle during installation.

4. Ease of Installation: PVC pipes can be joined easily using solvent cement, which is a faster and simpler method compared to the fusion welding used for PPR pipes.

PPR vs PVC Pipes: Key Differences

Let’s dive into the key differences between PPR pipes and PVC pipes, focusing on aspects like durability, temperature resistance, ease of installation, and cost.

1. Durability

Both PPR pipes and PVC pipes are durable, but PPR pipes have a longer lifespan. PPR pipes can last up to 50 years, while **PVC pipes generally have a lifespan of around 25 to 40 years. The superior durability of PPR pipes makes them more suitable for high-pressure, high-temperature applications, like heating systems.

Winner: PPR pipes

2. Temperature Resistance

PPR pipes outperform PVC pipes when it comes to temperature resistance. PPR pipes are capable of withstanding high temperatures of up to 95°C (203°F), making them ideal for both hot and cold water systems. In contrast, PVC pipes are best suited for cold water systems as they can start to soften at temperatures higher than 60°C (140°F).

Winner: PPR pipes

3. Cost

When it comes to cost, PVC pipes are more affordable than PPR pipes. The lower material cost and easier manufacturing process make PVC pipes an economical choice for low-budget projects, especially in applications like sewage and drainage systems.

Winner: PVC pipes

4. Ease of Installation

PPR pipes require a specialized fusion welding machine for installation, which can be more time-consuming and expensive. However, this method ensures stronger, leak-free joints. On the other hand, PVC pipes are joined using solvent cement, which is a quicker and simpler process, making installation more accessible for DIYers and smaller projects.

Winner: PVC pipes (for ease of installation)

5. Environmental Impact

Both PPR pipes and PVC pipes are made from plastic, but PPR pipes are considered more environmentally friendly. PPR pipes are made from recyclable polypropylene, which has a lower environmental impact during production and disposal. PVC pipes, on the other hand, contain chlorine and release harmful substances when burned or disposed of improperly.

Winner: PPR pipes

Ideal Applications for PPR and PVC Pipes

PPR Pipes:

– Hot Water System: Due to their excellent temperature resistance, PPR pipes are ideal for systems carrying hot water, such as underfloor heating and central heating systems.

– Potable Water Systems: PPR pipes are non-toxic and are suitable for drinking water applications.

– Industrial Applications: Their high pressure and temperature resistance make them a reliable choice for various industrial systems.

PVC Pipe

– Cold Water Systems: PVC pipes are most commonly used for cold water systems due to their low temperature resistance.

– Sewerage and Drainage: PVC pipes are commonly used for wastewater, sewage, and drainage systems due to their corrosion resistance and cost-effectiveness.

– Irrigation: The lightweight nature and easy installation of **PVC pipes** make them an excellent choice for irrigation systems.

Conclusion

Choosing between PPR pipes and PVC pipes ultimately depends on the specific needs of your project. **PPR pipes** are ideal for high-temperature, high-pressure systems, providing durability and long-term reliability. In contrast, **PVC pipes** are a more cost-effective option for low-pressure, cold water, and drainage systems. By understanding the key differences between these two materials, you can make an informed decision that best suits your plumbing needs.

Frequently Asked Questions (FAQ)

1. Can PPR pipes be used for both hot and cold water systems?

– Yes, PPR pipes can be used for both hot and cold water systems due to their high temperature resistance.

2. Are PVC pipes suitable for hot water applications?

– No, PVC pipes are not suitable for hot water applications, as they can soften at temperatures above 60°C (140°F).

3. Which is more environmentally friendly: PPR or PVC pipes?

– PPR pipes are more environmentally friendly than PVC pipes as they are made from recyclable polypropylene and do not contain chlorine.

4. How long do PPR and PVC pipes last?

– PPR pipes can last up to 50 years, while PVC pipes typically last between 25 to 40 years, depending on the application.

5. Which is easier to install: PPR or PVC pipes?

– PVC pipes are easier to install because they use solvent cement for joining, while PPR pipes require fusion welding, which is more complex and requires specialized equipment.

Related products