Description

One of the advantages of compression fittings is that they can be used with a wide variety of materials, including copper, stainless steel, titanium, and plastic. This versatility makes compression fittings a popular choice for many different types of piping systems. Additionally, compression fittings are relatively easy to install and can be tightened by hand or with a simple wrench. This means that they can be installed quickly and without the need for specialized tools or equipment.

However, there are also some disadvantages to compression fittings. One drawback is that they may leak if they are not installed correctly or if the seal is damaged. Additionally, compression fittings may not be suitable for high-pressure applications, as the seal may become compromised under excessive stress. Finally, compression fittings can be relatively expensive compared to other fitting options, especially if they are made of high-quality materials such as stainless steel.

Press Fittings

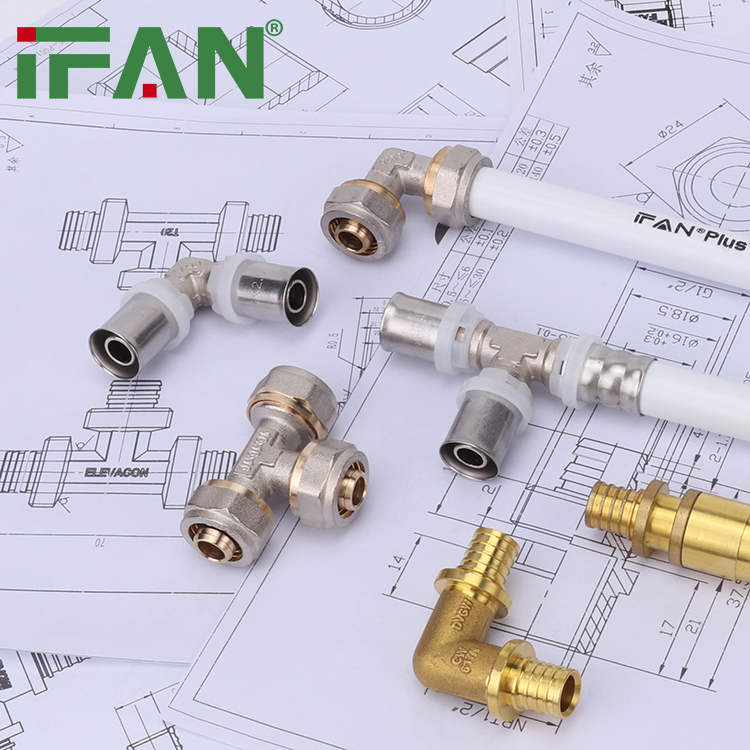

Press fittings are a type of fitting that use a special tool to crimp the fitting onto the pipe or tube. Press fittings are typically made of stainless steel or copper, and they consist of two main parts: a body and a seal. To install a press fitting, the pipe or tube is inserted into the body of the fitting, and the special pressing tool is used to crimp the fitting in place. This creates a tight and secure seal that is capable of withstanding high pressure.

One of the advantages of press fittings is that they are extremely reliable and rarely leak. Press fittings are typically rated for high-pressure applications and are often used in commercial and industrial piping systems. Additionally, press fittings are relatively easy to install, especially when compared to other fitting options such as welding or soldering. This means that press fittings can be installed quickly and with a minimal amount of specialized tools or equipment.

However, there are also some disadvantages to press fittings. One drawback is that they can be relatively expensive, especially if high-quality materials such as stainless steel are used. Additionally, press fittings require a special pressing tool to install, which can be expensive and may not be readily available in all situations. Finally, press fittings may not be suitable for all piping systems, as they may not be compatible with certain materials or applications.

Conclusion

In conclusion, both compression and press fittings are viable options for connecting pipes or tubes in a variety of applications. Both fitting types have their own unique advantages and disadvantages, and the best choice will depend on the specific needs of the piping system. Compression fittings are typically more versatile and can be used with a wide variety of materials, while press fittings are more reliable and better suited for high-pressure applications. Regardless of the choice, both compression and press fittings can be used to create a secure and leak-free piping system that can withstand the rigors of everyday use.

Related products

-

PEX Pipe fitting

IFAN PEX Press Fitting Tee