White PPR Fittings vs. Traditional Metal Fittings: Which is the Better Choice?

Introduction

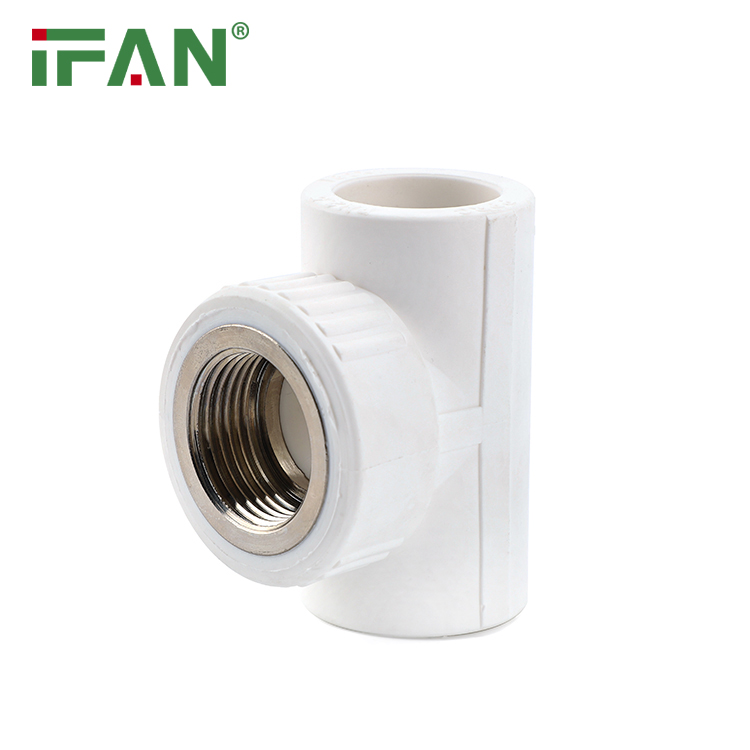

The choice between white PPR (polypropylene random copolymer) fittings and traditional metal fittings has been a subject of significant debate within the plumbing industry. Both options offer unique characteristics and advantages, prompting a closer examination to determine which represents the better choice for various plumbing applications. This article aims to compare white PPR fittings and traditional metal fittings across different criteria to provide insights into their respective strengths and limitations.

Corrosion Resistance

One of the primary considerations when evaluating plumbing fittings is their resistance to corrosion. While traditional metal fittings, such as copper or steel, are susceptible to rust and degradation over time, white PPR fittings exhibit exceptional corrosion resistance. The inherent properties of PPR material ensure that fittings maintain their structural integrity, even when exposed to aggressive water compositions or harsh chemicals. As a result, white PPR fittings offer superior long-term reliability in corrosive environments compared to traditional metal counterparts.

Installation Flexibility

White PPR fittings and traditional metal fittings differ in terms of installation flexibility. PPR fittings are lightweight and easy to handle, simplifying the installation process and reducing labor costs. Their compatibility with various joining methods, including heat fusion and mechanical connections, provides flexibility to plumbing professionals, allowing them to choose the most suitable technique for a specific application. In contrast, traditional metal fittings may require specialized tools and equipment for installation, potentially increasing project timelines and expenses.

Thermal Insulation and Energy Efficiency

In the context of thermal insulation and energy efficiency, white PPR fittings have a clear advantage over traditional metal fittings. The low thermal conductivity of PPR material helps maintain water temperature as it travels through the plumbing system, reducing heat loss and improving energy efficiency. This characteristic is particularly beneficial for hot water distribution, where minimizing heat dissipation translates to lower energy consumption and operational cost savings. Traditional metal fittings, on the other hand, are more prone to heat loss, potentially leading to increased energy demand and operational expenses.

Acoustic Performance

Another area of comparison lies in the acoustic performance of white PPR fittings versus traditional metal fittings. PPR fittings are known for their ability to dampen water flow-induced vibrations and reduce the transmission of sound through pipes and fittings. This feature contributes to quieter environments, making white PPR fittings an attractive choice for residential and commercial settings where noise control is essential for occupant comfort. Traditional metal fittings, while durable, may transmit more noise and vibration, potentially impacting the acoustic comfort of building occupants.

Cost Considerations

Cost is a significant factor in determining the better choice between white PPR fittings and traditional metal fittings. PPR fittings offer initial affordability, reduced labor costs due to their lightweight nature, and long-term savings through their durability and low maintenance requirements. In contrast, traditional metal fittings may involve higher material and installation costs, especially when specialized tools and skilled labor are required. While the upfront cost of PPR fittings may be lower, the long-term durability and reduced maintenance needs contribute to their overall cost-effectiveness.

Environmental Impact

When assessing the environmental impact, white PPR fittings demonstrate sustainability advantages over traditional metal fittings. The recyclability of PPR material aligns with circular economy principles, reducing waste and resource consumption. Additionally, the longevity of PPR fittings decreases the frequency of material replacement, contributing to conservation efforts and promoting responsible resource utilization. Traditional metal fittings, although durable, may have a higher environmental footprint due to production processes and end-of-life considerations.

Conclusion

In conclusion, the comparison between white PPR fittings and traditional metal fittings reveals distinct advantages for each option across various criteria. While traditional metal fittings have historically served as reliable plumbing components, white PPR fittings offer compelling benefits in terms of corrosion resistance, installation flexibility, thermal insulation, acoustic performance, cost-effectiveness, and environmental sustainability. Depending on specific project requirements and priorities, the unique characteristics of white PPR fittings position them as a preferred choice for modern plumbing installations, offering long-term reliability, efficiency, and environmental responsibility.