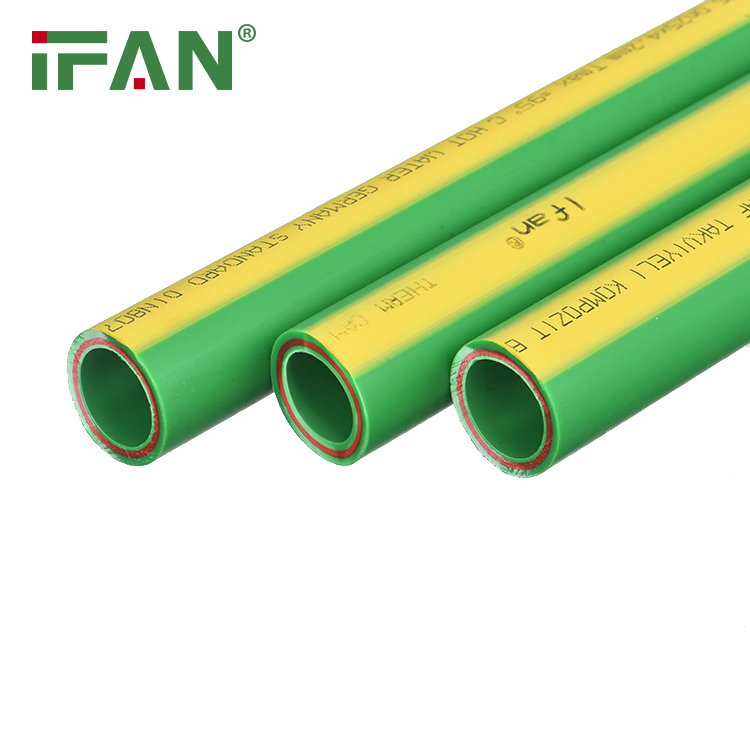

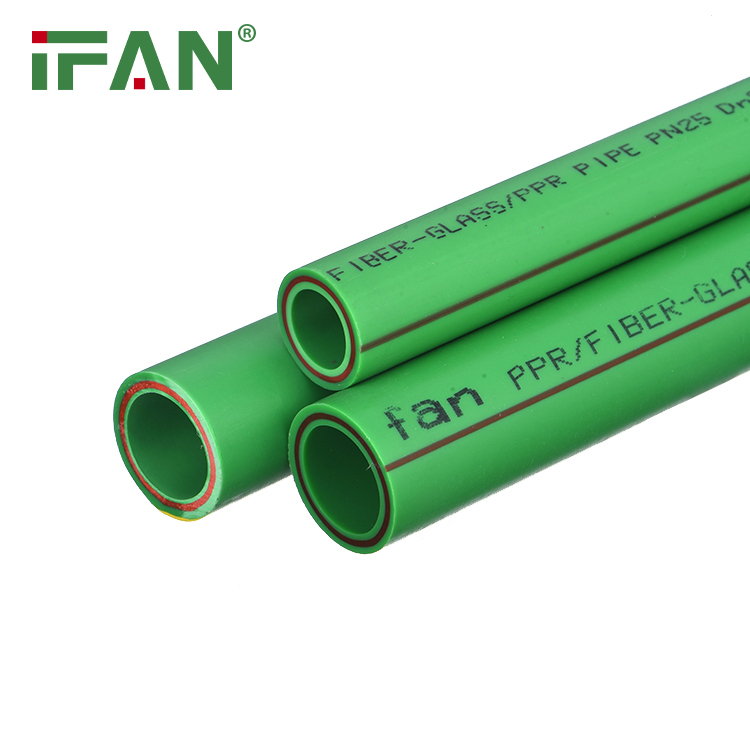

Advantages of PPR Fiberglass Pipes: Durability and Longevity

PPR (Polypropylene Random Copolymer) fiberglass pipes offer a range of advantages over traditional piping systems. These pipes combine the benefits of PPR material and fiberglass reinforcement, resulting in enhanced durability and longevity. In this comprehensive overview, we will explore the key advantages of PPR fiberglass pipes. Let’s break down each advantage into separate sections.

1. Exceptional Durability

PPR fiberglass pipes are highly durable, making them suitable for various applications. The combination of PPR material and fiberglass reinforcement provides excellent resistance to impact, external pressure, and mechanical stresses. These pipes can withstand harsh environmental conditions, including temperature fluctuations and corrosive substances, without compromising their structural integrity.

2. Corrosion Resistance

One of the major advantages of PPR fiberglass pipes is their exceptional resistance to corrosion. The PPR material used in these pipes does not react with most chemicals, ensuring the integrity of the pipe over its lifespan. The fiberglass reinforcement adds an extra layer of protection, making the pipes highly resistant to chemical attack and preventing the formation of rust or scaling.

3. Longevity

PPR fiberglass pipes have an impressive lifespan, outlasting many traditional piping materials. The combination of durable PPR material and reinforced fiberglass results in a pipe that can withstand the test of time. These pipes can operate reliably for decades, reducing the need for frequent replacements and lowering maintenance costs.

4. Smooth Inner Surface

The inner surface of PPR fiberglass pipes is exceptionally smooth, providing numerous benefits. The smooth surface minimizes frictional losses, ensuring efficient water flow and reducing energy consumption. It also prevents the buildup of deposits, such as rust or sediment, that can restrict flow and lead to clogging. The smooth inner surface of PPR fiberglass pipes helps maintain consistent water pressure throughout the system.

5. Thermal Resistance

PPR fiberglass pipes exhibit excellent thermal resistance properties. They can withstand high temperatures without deforming or losing their structural integrity. This makes them suitable for both hot and cold water applications, as well as heating systems. The thermal resistance of PPR fiberglass pipes ensures reliable performance and minimizes the risk of pipe failures due to temperature fluctuations.

6. Lightweight and Easy Installation

PPR fiberglass pipes are lightweight compared to traditional piping materials like metal or concrete. This makes them easier to handle, transport, and install. The lightweight nature of PPR fiberglass pipes reduces the need for heavy machinery during installation, making the process more efficient and cost-effective. Additionally, the flexibility of these pipes allows for easy maneuverability around obstacles and reduces the number of fittings required.

7. Environmental Benefits

PPR fiberglass pipes offer environmental advantages over other piping materials. They are recyclable, reducing waste generation and promoting sustainability. The production process of PPR fiberglass pipes consumes less energy compared to other materials, contributing to lower carbon emissions. The longevity of these pipes also reduces the need for replacements, further conserving resources.

Conclusion

The advantages of PPR fiberglass pipes, including exceptional durability, corrosion resistance, longevity, smooth inner surface, thermal resistance, ease of installation, and environmental benefits, make them a superior choice for various applications. By understanding and leveraging these advantages, users can benefit from a reliable and long-lasting piping system that meets their specific requirements.