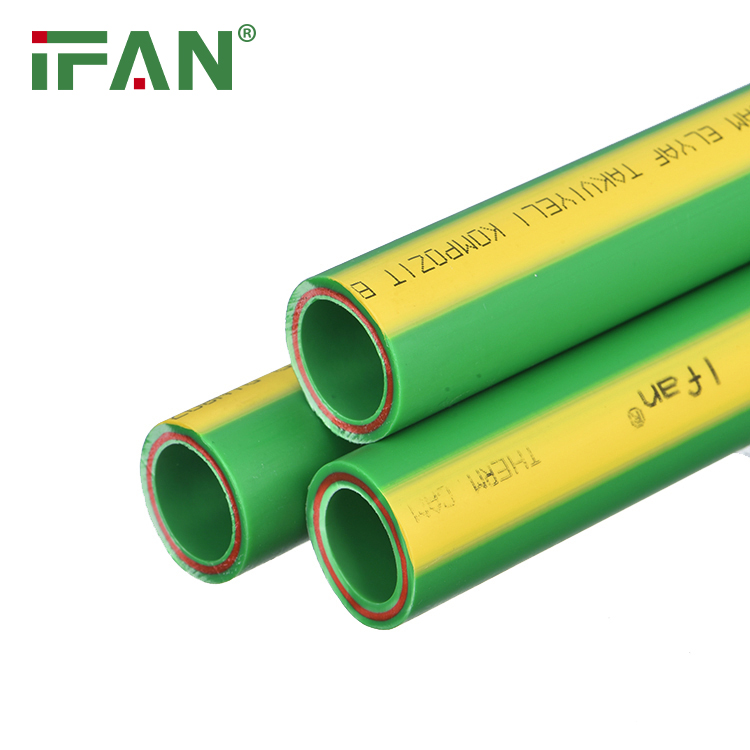

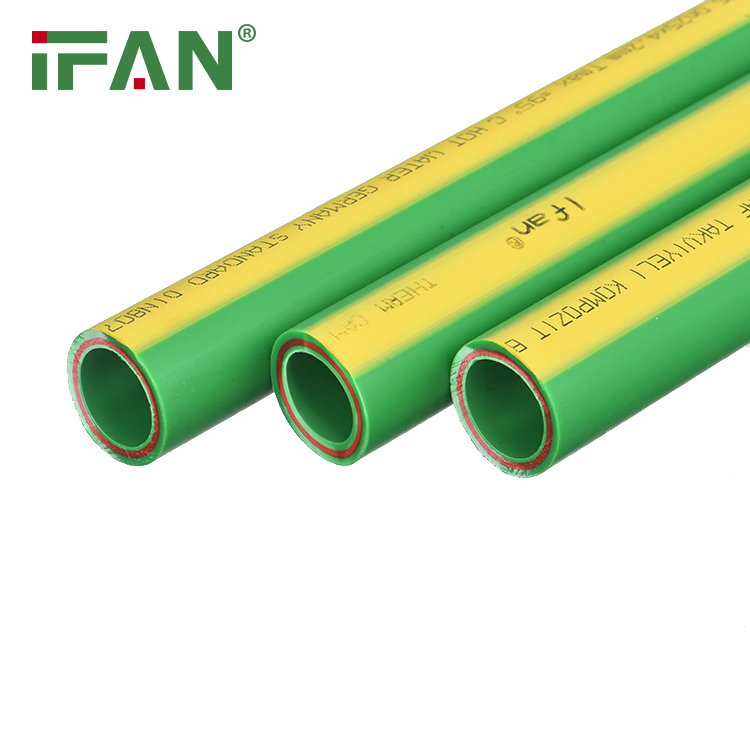

The Role of PPR Fiberglass Pipes in Plumbing Systems

PPR (Polypropylene Random Copolymer) fiberglass pipes play a crucial role in modern plumbing systems. These innovative pipes, combining the benefits of PPR material and fiberglass reinforcement, offer numerous advantages in terms of performance, reliability, and efficiency. In this comprehensive overview, we will explore the key aspects of the role of PPR fiberglass pipes in plumbing systems. Let’s break down each aspect into separate sections.

1. Water Supply Systems

PPR fiberglass pipes are commonly used in water supply systems, both for residential and commercial applications. Their smooth inner surface ensures efficient and uninterrupted water flow, reducing pressure losses and maintaining optimal water pressure throughout the system. The corrosion resistance of PPR fiberglass pipes ensures the delivery of clean and uncontaminated water, free from rust or chemical leaching.

2. Hot Water Distribution

One of the notable roles of PPR fiberglass pipes is their ability to handle hot water distribution. These pipes exhibit excellent thermal resistance, allowing them to withstand high temperatures without deformation or loss of structural integrity. PPR fiberglass pipes efficiently transport hot water from the source to various points of use, ensuring consistent water temperature and minimizing the risk of pipe failures due to thermal stress.

3. Drainage Systems

PPR fiberglass pipes are also utilized in drainage systems, efficiently carrying wastewater away from buildings. Their smooth inner surface prevents clogging and facilitates the smooth flow of wastewater, reducing the risk of blockages. The durability and corrosion resistance of PPR fiberglass pipes ensure long-lasting performance in drainage applications, minimizing the need for maintenance or replacements.

4. Leak-free Connections

The installation of PPR fiberglass pipes involves heat fusion techniques, which create strong and leak-free connections. These connections are highly reliable and ensure the integrity of the plumbing system. The smooth and homogeneous fusion joints of PPR fiberglass pipes eliminate potential leakage points, reducing the risk of water damage and ensuring the efficient operation of the plumbing system.

5. Resistance to Chemicals

PPR fiberglass pipes exhibit excellent resistance to a wide range of chemicals, making them suitable for various plumbing applications. They can withstand the corrosive effects of chemicals present in water or other fluids, ensuring the long-term performance of the plumbing system. The chemical resistance of PPR fiberglass pipes minimizes the risk of pipe degradation, leaks, or contamination of the water supply.

6. Noise Reduction

PPR fiberglass pipes contribute to noise reduction in plumbing systems. Their dense structure and smooth inner surface minimize water flow noise, providing a quieter operation compared to traditional piping materials. This is particularly beneficial in residential settings, where noise reduction enhances comfort and the overall living experience.

7. Cost Efficiency

The use of PPR fiberglass pipes in plumbing systems brings cost-efficiency benefits. These pipes have a longer lifespan compared to traditional materials, reducing the need for frequent replacements and associated costs. The low maintenance requirements of PPR fiberglass pipes further contribute to cost savings over the lifetime of the plumbing system. Additionally, the ease of installation of these pipes reduces labor costs and installation time.

Conclusion

The role of PPR fiberglass pipes in plumbing systems is crucial for delivering clean, efficient, and reliable water supply and drainage solutions. With their outstanding performance in water distribution, hot water handling, chemical resistance, leak-free connections, noise reduction, and cost efficiency, PPR fiberglass pipes have become increasingly popular in various plumbing applications. By understanding the role and benefits of PPR fiberglass pipes, users can make informed decisions and ensure the optimal performance of their plumbing systems