Introduction

Urban housing projects are essential for accommodating the growing population in cities, providing safe and affordable living spaces. One of the critical components of these projects is the water supply system, which ensures residents have access to clean and safe water. This report focuses on the use of Polypropylene Random Copolymer (PPR) pipes in the water supply scheme for an urban housing project. It discusses the features, benefits, and implementation of PPR pipes, highlighting their role in enhancing the overall efficiency and sustainability of urban water supply systems.

Understanding PPR Pipes

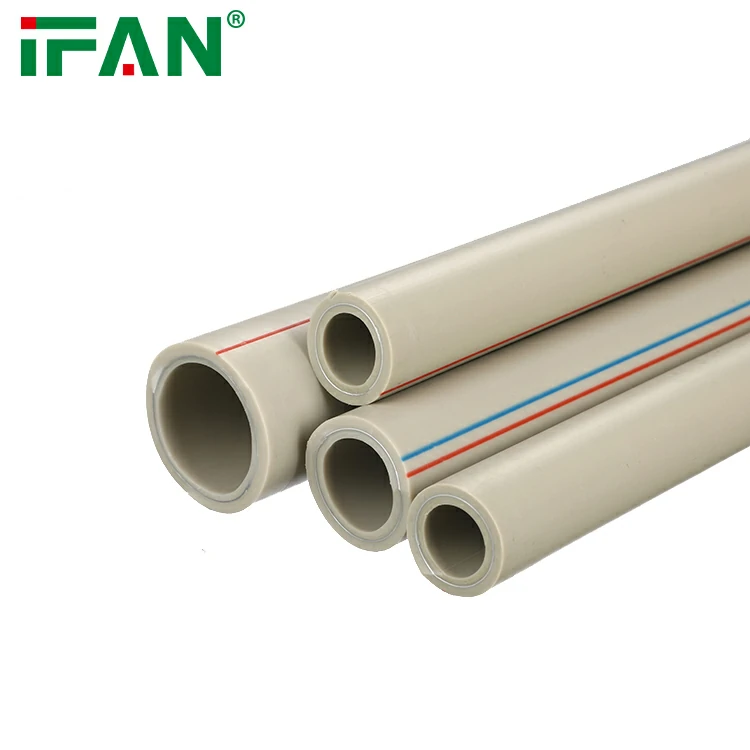

What Are PPR Pipes?

PPR pipes are made from polypropylene random copolymer, a thermoplastic polymer known for its durability, lightweight nature, and resistance to chemicals and high temperatures. PPR pipes are widely used in plumbing and piping systems, particularly for hot and cold water supply applications. Their versatility and reliability make them a preferred choice in modern construction practices.

Key Features of PPR Pipes

- Durability: PPR pipes have a long lifespan, often exceeding 50 years, making them a cost-effective solution for urban housing projects.

- Temperature Resistance: These pipes can withstand temperatures up to 95°C (203°F), making them suitable for both hot and cold water applications.

- Lightweight: PPR pipes are significantly lighter than traditional materials like metal, facilitating easier handling and installation.

- Corrosion Resistance: PPR pipes do not corrode, ensuring that they maintain their structural integrity over time and reducing the risk of leaks.

- Low Maintenance: Due to their resistance to scaling and corrosion, PPR pipes require minimal maintenance, resulting in lower long-term costs for homeowners and developers.

Importance of Water Supply in Urban Housing Projects

Access to Clean Water

Access to clean water is a fundamental human right and crucial for public health. In urban housing projects, ensuring a reliable water supply system is essential for the well-being of residents. PPR pipes contribute to this goal by providing a safe and efficient means of transporting water to households.

Efficiency in Water Management

An efficient water supply system is vital for managing resources effectively in urban areas. PPR pipes enable optimal flow rates and pressure management, ensuring that water is delivered to residents without interruptions. This efficiency is particularly important in densely populated urban environments where demand for water is high.

Compliance with Regulations

Urban housing projects must adhere to local building codes and regulations regarding water supply systems. PPR pipes meet international standards for safety and quality, ensuring compliance and contributing to the overall integrity of the housing project.

Implementation of PPR Pipe Supply Scheme

Project Overview

The urban housing project in question aims to provide affordable housing solutions for low- to middle-income families. The project includes the installation of a comprehensive water supply system that utilizes PPR pipes for efficient water delivery.

Planning and Design

- Assessment of Water Demand: A thorough assessment of the water demand for the housing project was conducted, considering factors such as the number of units, average household size, and peak usage times.

- System Design: Based on the demand assessment, a detailed design of the water supply system was developed, incorporating PPR pipes for main lines, branch lines, and connections to individual units.

- Material Selection: PPR pipes were selected due to their superior performance characteristics, including durability, resistance to temperature fluctuations, and low maintenance requirements.

Procurement of PPR Pipes

The procurement process involved selecting a reputable supplier that could provide high-quality PPR pipes in the required specifications. Factors considered during procurement included:

- Quality Assurance: The supplier’s commitment to quality and compliance with industry standards was a critical consideration.

- Cost-Effectiveness: While ensuring quality, the project team sought to secure competitive pricing to stay within budget constraints.

- Timely Delivery: The supplier’s ability to deliver materials on time was essential to keep the project on schedule.

Installation Process

- Training and Workforce Development: The installation team underwent training on the proper handling and installation techniques for PPR pipes to ensure a successful implementation.

- Installation Techniques: PPR pipes were installed using heat fusion techniques to create secure and leak-proof joints. This method ensures the integrity of the water supply system and minimizes the risk of future leaks.

- Testing and Quality Control: After installation, the entire water supply system was tested for leaks and pressure integrity. This quality control measure ensured that the system met the required performance standards before being put into operation.

Benefits of Using PPR Pipes in Urban Housing Projects

Enhanced Water Quality

PPR pipes do not leach harmful substances into the water supply, ensuring that residents receive clean and safe drinking water. This quality is particularly important in urban environments where water contamination can be a concern.

Cost Savings

The long lifespan and low maintenance requirements of PPR pipes translate to significant cost savings for both developers and residents. Reduced maintenance needs mean lower long-term expenses for homeowners, making housing more affordable.

Sustainability

PPR pipes are recyclable and contribute to sustainable building practices. Using eco-friendly materials aligns with the growing emphasis on sustainability in construction and urban development.

Increased Property Value

Properties equipped with modern, efficient water supply systems tend to have higher market values. The use of PPR pipes can enhance the overall appeal of the housing project, attracting potential buyers and investors.

Challenges and Considerations

Initial Investment

While PPR pipes offer long-term savings, the initial investment may be higher compared to traditional materials. Developers must weigh the upfront costs against the long-term benefits when making material selections.

Market Awareness

There may be a lack of awareness among contractors and developers regarding the advantages of PPR pipes. Education and outreach efforts are essential to promote their benefits and encourage adoption in future projects.

Compliance with Standards

Ensuring compliance with local building codes and regulations is crucial. Developers must stay informed about relevant standards and ensure that all materials and installation practices meet these requirements.

Conclusion

The implementation of a PPR pipe supply scheme in urban housing projects represents a significant step toward improving water supply systems in densely populated areas. The durability, efficiency, and sustainability of PPR pipes make them an ideal choice for modern construction practices. By prioritizing the use of high-quality materials, urban housing projects can ensure that residents have access to clean and safe water, contributing to their overall well-being and quality of life.

Frequently Asked Questions (FAQs)

1. What are PPR pipes used for in urban housing projects?

PPR pipes are used for transporting hot and cold water in plumbing systems, ensuring efficient and safe water supply to residential units.

2. What are the advantages of using PPR pipes over traditional materials?

PPR pipes offer durability, lightweight construction, corrosion resistance, low maintenance requirements, and enhanced water quality compared to traditional materials.

3. How long do PPR pipes last?

PPR pipes can last over 50 years under normal conditions, making them a long-term investment for water supply systems.

4. Are PPR pipes eco-friendly?

Yes, PPR pipes are recyclable and do not leach harmful substances into the water supply, making them an environmentally friendly choice for construction.

5. What installation techniques are used for PPR pipes?

PPR pipes are typically installed using heat fusion techniques, which create secure and leak-proof joints, ensuring the integrity of the water supply system.