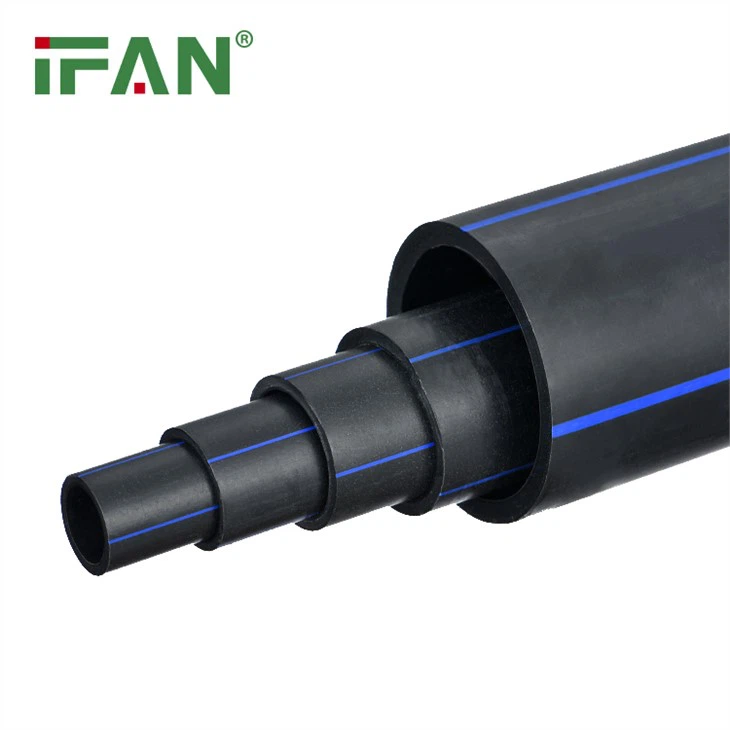

HDPE Pipe and Fabricated Fittings: A Comprehensive Overview

HDPE (high-density polyethylene) pipe and fabricated fittings are widely used in various industries and applications due to their excellent properties and versatility. In this comprehensive overview, we will explore the characteristics of HDPE pipe and the benefits of using fabricated fittings. Additionally, we will discuss the different types of fabricated fittings commonly used with HDPE pipes.

Fabricated Fittings

Fabricated fittings are custom-made components used to connect, branch, or adapt HDPE pipes to meet specific project requirements. These fittings offer several advantages, including:

- Precision and Customization: Fabricated fittings are manufactured to precise specifications, ensuring a perfect fit and alignment with the HDPE pipes. They can be custom-made to accommodate various pipe diameters and angles.

- Durability: Fabricated fittings are constructed from high-quality HDPE material, ensuring strength and durability. They are resistant to chemicals, corrosion, and impact, prolonging the lifespan of the piping system.

- Versatility: Fabricated fittings provide versatility in design and functionality. They can be used to create complex configurations, such as tees, elbows, reducers, and flanges, enabling seamless integration into any project.

- Ease of Installation: Fabricated fittings are designed for easy installation, reducing labor and time requirements. They often feature mechanical joints or fusion connections, ensuring a secure and leak-free joint.

Types of Fabricated Fittings

There is a wide range of fabricated fittings available for HDPE pipes, catering to different applications and installation requirements. Here are some commonly used fabricated fittings:

- Tees and Elbows: These fittings allow for branching and changing the direction of the pipeline. They come in various angles and sizes to accommodate different configurations.

- Reducers and Increasers: Used to transition between pipes of different diameters, these fittings ensure a smooth flow and reduce the risk of pressure losses.

- Flanges: Flanged fittings provide a bolted connection between the HDPE pipe and other equipment or components. They are commonly used in applications that require easy disassembly or access.

- Manifolds: Manifolds are fabricated fittings that distribute fluid flow into multiple directions. They are often used in irrigation systems, water distribution networks, and industrial applications.

Conclusion

HDPE pipe and fabricated fittings offer a versatile and reliable solution for various piping applications. With their exceptional properties, including high strength, chemical resistance, and longevity, HDPE pipes provide a cost-effective and sustainable choice. Fabricated fittings further enhance the flexibility and functionality of HDPE piping systems, allowing for precise connections and customization. By utilizing HDPE pipe and fabricated fittings, you can create a robust and efficient piping infrastructure that meets your project requirements.