What are PPR Tubes and How Do They Work?

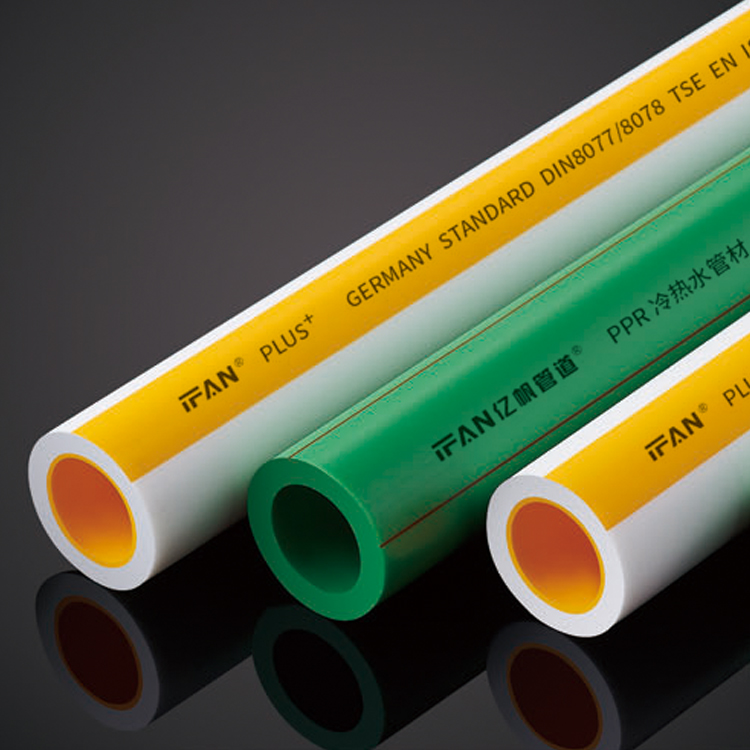

Polypropylene Random Copolymer (PPR) tubes are a type of plastic plumbing pipe that have gained popularity in recent years. These pipes are made from a special type of plastic that is durable, flexible, and resistant to chemicals and heat. Unlike traditional metal or PVC pipes, PPR tubes can be easily welded together using a heating tool, creating a seamless and leak-proof connection.

Benefits of Using PPR Tubes

There are several benefits to using PPR tubes for plumbing projects. Firstly, they are lightweight and easy to install – making them a popular choice for DIY enthusiasts. Secondly, they are corrosion-resistant and long-lasting, meaning that they won’t rust or degrade over time like traditional metal pipes. Finally, PPR tubes are eco-friendly, as they can be recycled and reused once they reach the end of their lifespan.

Applications of PPR Tubes

PPR tubes are suitable for a wide range of plumbing applications, including hot and cold water supply, underfloor heating systems, and even compressed air lines. Due to their flexible nature, PPR tubes can also be used to create complex layouts and shapes, making them ideal for custom installations.

Maintenance and Repair of PPR Tubes

One of the main advantages of PPR tubes is that they require minimal maintenance once installed. However, if a repair is needed, it can be easily done by cutting out the damaged section and welding in a new piece. This is much simpler than repairing traditional metal or PVC pipes, which often require extensive digging and excavation.

Conclusion

Overall, PPR tubes offer a range of benefits over traditional metal or PVC pipes. They are lightweight, corrosion-resistant, and eco-friendly, making them a popular choice for modern plumbing projects. As the world becomes more conscious of environmental