Minimal Downtime with HDPE Fittings

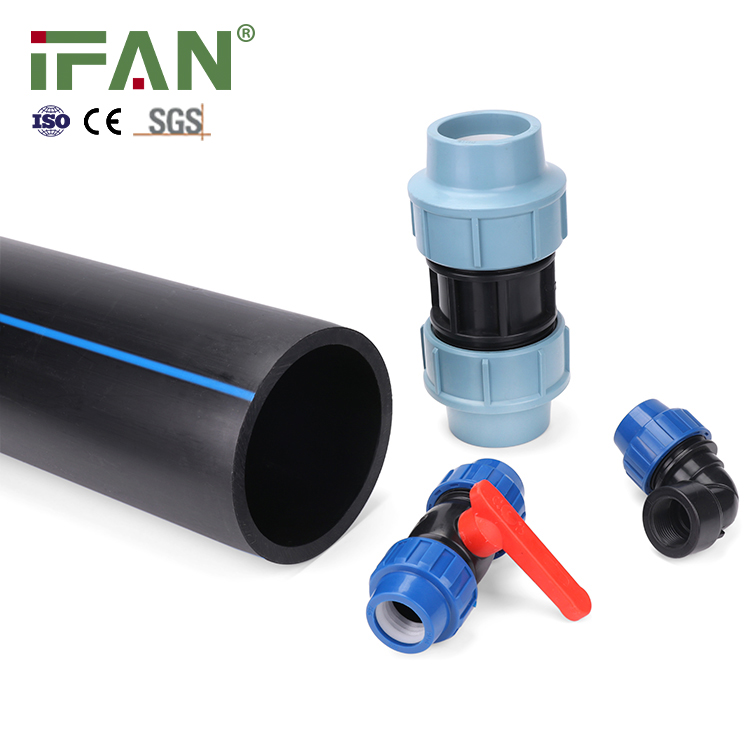

As industries and infrastructures continue to grow, the need for durable, reliable, and efficient piping systems becomes more apparent. High-density polyethylene (HDPE) fittings have become a popular choice for many applications, offering a range of benefits that make them ideal for modern piping systems. One such benefit is the ability to minimize downtime.

HDPE fittings are designed to be installed quickly and easily, reducing the time required to complete a piping project. Unlike traditional piping systems, which often require extensive welding or gluing, HDPE fittings can be joined using a variety of methods, such as butt fusion or electrofusion. These methods result in a strong, leak-proof bond that can be completed in a matter of minutes, minimizing the amount of time that systems need to be shut down for installation.

In addition, HDPE fittings have a long lifespan, making them an ideal choice for applications where uptime is critical. HDPE is resistant to corrosion, abrasion, and chemical attack, making it an ideal material for use in harsh environments. This means that HDPE fittings can continue to perform reliably for years, reducing the need for frequent maintenance and repair work, which can lead to extended downtime.

One of the key advantages of HDPE fittings is their ability to be customized to meet specific project requirements. HDPE fittings can be manufactured in a variety of sizes and shapes, allowing them to seamlessly integrate into existing systems or accommodate new design features. This flexibility reduces the amount of time and effort required to incorporate HDPE fittings into a project, further reducing downtime.

Another advantage of HDPE fittings is their relatively low cost compared to traditional piping materials. The low cost of HDPE fittings means that industries and infrastructures can benefit from the many advantages of HDPE without breaking the bank. This makes it possible to invest in reliable and durable piping systems that won’t require costly repairs or replacement work down the line.

In conclusion, HDPE fittings offer an attractive option for many industries and infrastructures seeking to minimize downtime. With their quick and easy installation process, long lifespan, flexibility, and low cost, HDPE fittings can provide a reliable and efficient solution for any piping project. By investing in HDPE fittings, businesses can minimize downtime, reduce the risk of costly repairs, and maximize uptime, all while benefiting from the many other advantages that HDPE has to offer.