Introduction

PPR (Polypropylene Random Copolymer) fiberglass pipes are known for their exceptional chemical resistance properties. Understanding the chemical resistance of these pipes is crucial for their effective and safe application in various industries. In this article, we will delve into the key aspects of the chemical resistance of PPR fiberglass pipes. Let’s break down each section into separate headings.

1. Chemical Composition of PPR Fiberglass Pipes

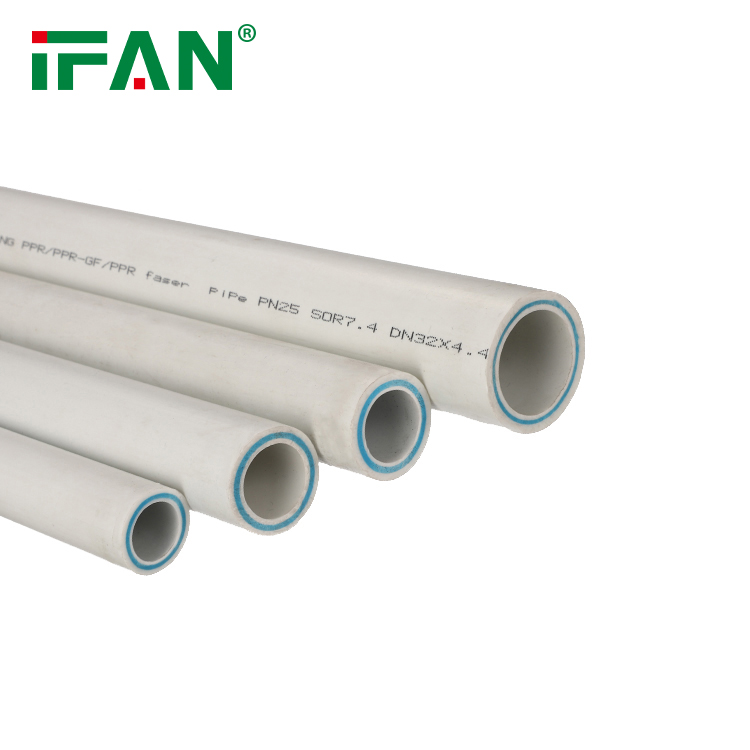

PPR fiberglass pipes are composed of a combination of polypropylene, a thermoplastic polymer, and fiberglass reinforcement. The polypropylene imparts excellent chemical resistance to the pipes, while the fiberglass layer enhances their strength and durability. This composition provides a robust foundation for the pipes to resist the effects of different chemicals encountered in various applications.

2. Resistance to Acids and Alkalis

PPR fiberglass pipes exhibit high resistance to a wide range of acids and alkalis, making them suitable for applications where these substances are present. Acids with different levels of concentration, such as sulfuric acid, hydrochloric acid, and nitric acid, do not significantly affect the integrity or performance of PPR fiberglass pipes. Similarly, strong alkalis like sodium hydroxide and potassium hydroxide do not cause any degradation or damage to the pipes. This resistance ensures the safe transport of various chemicals without compromising the pipes’ structural integrity.

3. Resistance to Organic Solvents

Organic solvents, commonly used in industries such as manufacturing, pharmaceuticals, and laboratories, can have detrimental effects on many materials. However, PPR fiberglass pipes exhibit excellent resistance to organic solvents, including alcohols, ketones, esters, and hydrocarbons. This resistance allows for the safe and reliable transportation of solvents without the risk of pipe degradation, ensuring the integrity and efficiency of the system.

4. Resistance to Oxidizing Agents

Oxidizing agents, such as chlorine, hydrogen peroxide, and ozone, can be highly reactive and corrosive to many materials. PPR fiberglass pipes demonstrate remarkable resistance to oxidizing agents, even at elevated temperatures and concentrations. They can withstand the harsh effects of these agents without experiencing degradation, ensuring the longevity and reliability of the pipes in applications such as water treatment facilities, swimming pools, and chemical processing plants.

5. Resistance to Salts and Minerals

PPR fiberglass pipes are highly resistant to salts and minerals commonly found in water and other fluids. They can withstand the corrosive effects of substances like calcium, magnesium, and chloride ions. This resistance is vital in applications involving the transportation of water, brine, or other solutions with high mineral content. PPR fiberglass pipes maintain their structural integrity and prevent scale buildup, ensuring efficient fluid flow and minimizing maintenance requirements.

6. Limitations and Considerations

While PPR fiberglass pipes exhibit exceptional chemical resistance, it is essential to consider the specific chemicals and conditions involved in each application. Some highly aggressive chemicals or extreme temperature and pressure conditions may require additional measures or alternative materials. Consulting with experts and conducting thorough chemical compatibility tests is crucial to ensure the suitability and longevity of PPR fiberglass pipes in specific chemical environments.

Conclusion

Understanding the chemical resistance of PPR fiberglass pipes is vital for their successful application in various industries. Their resistance to acids, alkalis, organic solvents, oxidizing agents, salts, and minerals makes them a reliable choice for transporting a wide range of fluids. However, it is important to consider the specific chemicals and conditions to ensure their compatibility. By leveraging the exceptional chemical resistance properties of PPR fiberglass pipes, industries can achieve safe and efficient fluid transportation while minimizing the risk of pipe degradation or failure.