Introduction

When it comes to PEX (cross-linked polyethylene) plumbing systems, there are two primary methods for connecting PEX pipes: expansion and crimp. Both methods have their advantages and considerations. In this article, we will compare expansion and crimp PEX connections to determine which method is better suited for various applications.

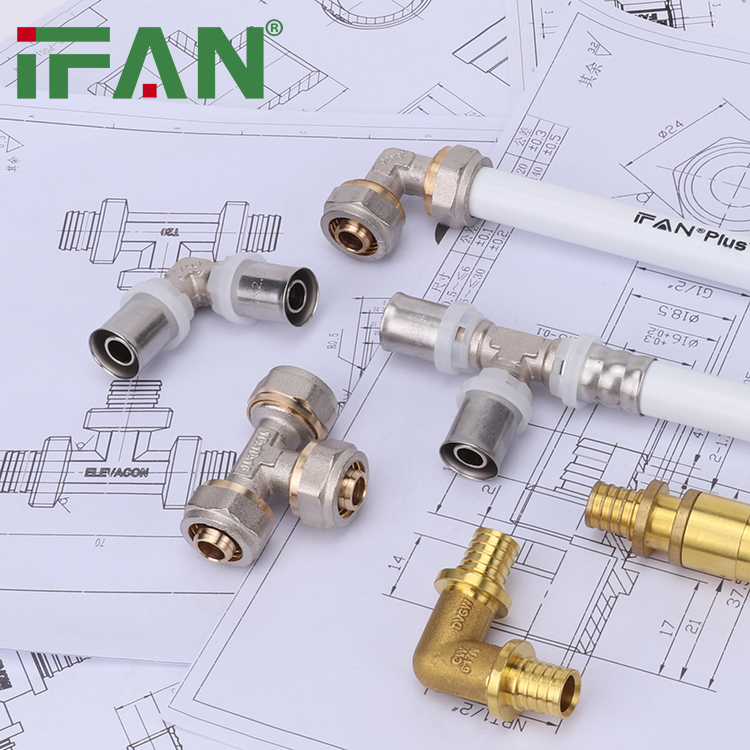

Expansion PEX Connections

Expansion PEX connections involve the use of an expansion tool to enlarge the pipe diameter temporarily. The expanded pipe is then inserted onto a fitting, and as the pipe contracts back to its original size, it creates a tight and secure connection.

Advantages of Expansion PEX Connections

- Leak Resistance: Expansion PEX connections provide a high level of leak resistance due to the tight connection created during the contraction process. This can be particularly beneficial in applications where minimizing the risk of leaks is crucial.

- Easy Installation: The expansion PEX method is relatively easy to install, especially in tight or hard-to-reach spaces. The expansion tool can rotate 360 degrees, allowing for flexibility during installation.

- No Use of Chemicals or Solvents: Expansion PEX connections do not require the use of chemicals or solvents, making them a more environmentally friendly option. This can be particularly advantageous in applications where the use of chemicals is restricted.

- Reduced Risk of Damage: Since the expansion tool does not pose a direct force on the pipe, there is a reduced risk of damaging the PEX pipe during the connection process. This can help maintain the integrity and lifespan of the pipes.

Considerations for Expansion PEX Connections

- Cost of Tools: Expansion PEX connections require the use of specialized expansion tools, which can be more expensive compared to crimping tools. However, the cost may be justified by the benefits offered by expansion connections.

- Limited Fitting Options: Expansion PEX connections are compatible with a specific range of fittings designed for expansion connections. The availability of fittings may vary, and it is important to ensure that the required fittings are readily accessible for the specific application.

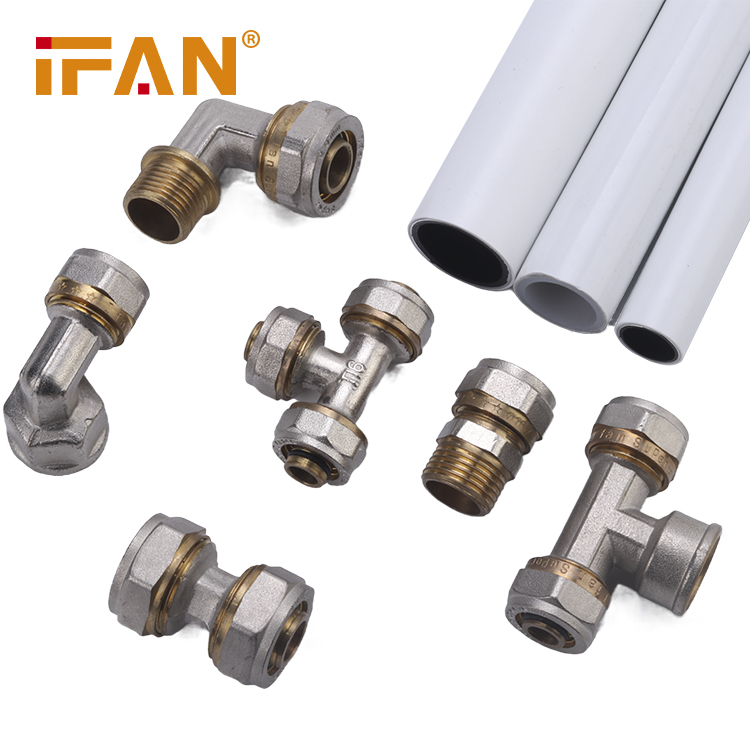

Crimp PEX Connections

Crimp PEX connections involve the use of a crimping tool and copper crimp rings to secure the PEX pipe onto a fitting. The crimp ring is placed over the pipe and fitting, and the crimping tool is used to compress the ring, creating a secure connection.

Advantages of Crimp PEX Connections

- Cost-Effectiveness: Crimp PEX connections are generally less expensive because they do not require specialized tools like expansion connections. The crimping tool and copper crimp rings are widely available and affordable.

- Wide Range of Fittings: Crimp PEX connections offer a broader range of fitting options compared to expansion connections. This versatility allows for greater flexibility when designing and installing plumbing systems.

- Time-Tested Method: Crimp PEX connections have been used for many years and have a proven track record of reliability and durability. They have been widely accepted and used in numerous plumbing applications.

Considerations for Crimp PEX Connections

- Potential for Leaks: Crimp PEX connections, while generally reliable, may have a slightly higher risk of leaks compared to expansion connections. Proper installation techniques, including proper calibration of the crimping tool, are essential to minimize this risk.

- Limited Access in Tight Spaces: The crimping tool requires sufficient space to maneuver, which can be challenging in tight or confined areas. This can result in difficulties during installation or repairs.

- Use of Copper Crimp Rings: Crimp PEX connections rely on copper crimp rings, which can be susceptible to corrosion in certain environments. Proper selection and installation of the rings are crucial to ensure long-term performance.

Conclusion

Both expansion and crimp PEX connections have their advantages and considerations. Expansion PEX connections offer excellent leak resistance, ease of installation, and no need for chemicals or solvents. On the other hand, crimp PEX connections are cost-effective, offer a wide range of fitting options, and have a proven track record of reliability.

The choice between expansion and crimp PEX connections ultimately depends on the specific application, budget, and personal preference. It is essential to consider factors such as installation space, available fittings, potential for leaks, and the cost of tools before deciding on the preferred method. Consulting with a plumbing professional can provide valuable insights and recommendations based on the specific requirements of your plumbing project.